Navigating Load Challenges with Custom Engineered Wheels

In every industry, moving heavy loads is a daily task. The right wheels can make this task safer and more efficient. This article talks about custom engineered wheels and their role in different sectors.

We’ll explore how these wheels are designed and the materials used for tough jobs. Real-world examples show how custom solutions have solved complex problems.

Plus, we’ll guide you in choosing the right wheels for your needs. Whether it’s improving efficiency or ensuring worker safety, the right wheel choice matters.

The Foundation of Custom Engineered Wheels in the Caster Industry

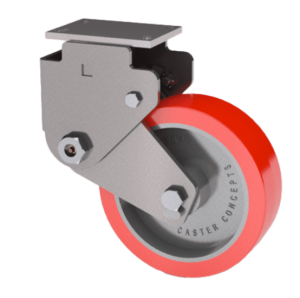

Custom caster wheels play a key role in moving heavy things smoothly and efficiently. These wheels are specially made to fit the unique needs of different jobs. In the caster industry, this means creating wheels that can handle different weights, work on various floor types, and operate in a range of environments.

In making these wheels, the industry looks closely at what each customer needs. This means considering how heavy the loads are, what the floors in the workplace are like, and the overall conditions where the wheels will be used. From there, experts use their knowledge to create a wheel that matches these requirements perfectly.

This focus on custom solutions shows how diverse the caster industry is. It’s all about finding the right fit for each unique challenge. This approach helps industries keep things moving smoothly, no matter how tough the job might be.

Design and Material Considerations for Heavy-Duty Applications

Choosing the Right Materials:

- Steel and Polyurethanes: For tough jobs, steel and polyurethanes stand out. Steel handles extreme weights. Polyurethanes work well on rough surfaces. Both materials ensure durability.

- Rubber and Pneumatic: Rubber wheels offer smooth rides. Pneumatic options are great for outdoor use. They absorb shocks well.

- Phenolic and Nytec: Phenolic resists water and oil. Nytec is light and strong. Both are good for special applications.

Caster Design:

- Kingpin Casters: Traditional and adjustable. They can be tightened to control movement. Good for uneven floors.

- Kingpinless Casters: They handle heavy loads better. With fewer parts, they last longer. They move smoothly under weight.

- Spring-loaded Casters: These wheels smooth out bumps. They protect the load and reduce noise. Ideal for uneven surfaces.

- Maintenance-Free Casters: These casters need less upkeep. Sealed bearings keep out dirt. They stay smooth without greasing.

Design Considerations

- Wheel Diameter: Bigger wheels roll more easily and can carry more weight. They’re better for moving heavy loads smoothly across various surfaces.

- Tread Width: Wider treads distribute weight more evenly. This means less stress on the wheel and smoother movement, especially for heavy items.

Advanced Technology in Action:

American Muscle Casters Handle the Heaviest Loads: These casters can move up to 250,000 lbs. Made in the USA, they are built for strength and durability.

Caster Concepts offers customization on their designs. You can choose the features you need, and their experts will make it happen. This means you get wheels that are perfect for your specific needs.

Case Studies: Custom Engineered Wheels in Action

Custom Engineered Wheels: Solving Aerospace Challenges

● Massive Fuselage Assembly Overhaul:

A major airplane maker needed to move huge 48,000-pound platforms. They found a solution with custom dual-wheel casters from Caster Concepts. These casters made moving the platforms easy and safe.

● Special Casters for Tooling:

A tooling fabricator working for a big aerospace company needed unique casters. They got the largest TWERGO wheels ever, designed for 14,000 pounds. Caster Concepts offered these wheels. Safety features were added to meet specific needs.

● Boeing 787 Dreamliner Custom Solutions:

While building the Boeing 787 Dreamliner, a tough challenge arose when moving a part weighing 35,000 pounds. Caster Concept created a custom swivel caster wheel that worked well on uneven floors and tight spaces.

Caster Concept’s Commitment to Overcoming Challenges

No job is big or small for their team. They specialize in making possible, what seems impossible. Whether it’s moving heavy loads or navigating tight spaces, they are here to help.

These real-world cases show how custom wheels can solve complex problems. From aerospace to manufacturing, the right wheels make all the difference.

Hauling Heavy Loads: A Custom Wheel Solution

● The Challenge with Heavy Equipment:

A global equipment manufacturer faced a big problem. They needed to move heavy equipment, up to 60,000 lbs., without causing damage. Their old method used different carts and wheels, leading to inefficiency and accidents.

● Finding the Right Solution:

Caster Concepts’ team, led by Matt Feichter and Doug Backinger, stepped in. They analyzed the situation right at the facility. Their goal was to find one type of caster that could handle all conditions and loads.

● The Perfect Caster for the Job:

They chose the 99 Series Extra-Heavy-Duty Dual Wheel Caster. This caster was a match for the plant’s needs. It worked well in all areas, supported heavy weights, and made moving equipment smoother.

The Outcome

With the new casters, moving heavy equipment became safer and more efficient. The risk of accidents dropped. The equipment stayed in good shape, and the process became streamlined.

This case shows how the right custom wheel solution can solve big problems. It makes moving heavy loads safer and easier.

Choosing the Right Custom Wheel Solution for Your Needs

Selecting the right wheels for your operations is crucial. It can make moving loads easier, safer, and more efficient. Here’s how to choose the best custom engineered wheels for your needs.

Assess Your Operational Needs:

- Load Capacity: Know the weight of what you’ll be moving. Heavier loads require stronger wheels.

- Speed Requirements: Consider how fast the wheels need to move. Faster speeds might need wheels designed for minimal resistance.

- Environmental Conditions: Think about where the wheels will be used. Conditions like extreme temperatures or exposure to chemicals affect wheel choice.

- Maintenance Considerations: Some wheels are easier to maintain than others. Choose based on your ability to perform regular maintenance.

Before choosing a wheel, understand your operation’s specific needs. This ensures you get wheels that can handle your tasks.

The Consultation Process:

- Effective Communication: Clearly describe what you need. Include details about load, speed, environment, and maintenance.

- Partner with Experts: Choose a company known for custom solutions and strong support. Their expertise can guide you to the right choice.

Talking to experts helps match your needs with the perfect wheel solution. A good partner will listen and offer tailored advice.

Benefits of Custom Solutions:

- Improved Efficiency: The right wheels can speed up operations without sacrificing safety.

- Reduced Wear on Equipment: Properly selected wheels minimize damage to both the wheels and the floors.

- Enhanced Worker Safety: The correct wheels can reduce accidents and make handling heavy loads safer.

Investing in custom wheel solutions pays off. It brings efficiency, safety, and durability to your operations.

Get Your Custom Engineered Wheels from Caster Concepts

Custom engineered wheels play a crucial role in handling heavy loads across various industries. These custom solutions bring unmatched benefits in performance, safety, and cost savings.

Caster Concepts specializes in designing wheels that meet specific operational needs, ensuring smooth and efficient processes. By choosing custom caster wheels, businesses make a strategic investment in their operational infrastructure.

For anyone facing challenges with moving heavy loads, reaching out to Caster Concepts can be a game-changing decision. Consider it an investment in improving your operations. Contact Caster Concepts today for expert guidance on custom engineered wheels.